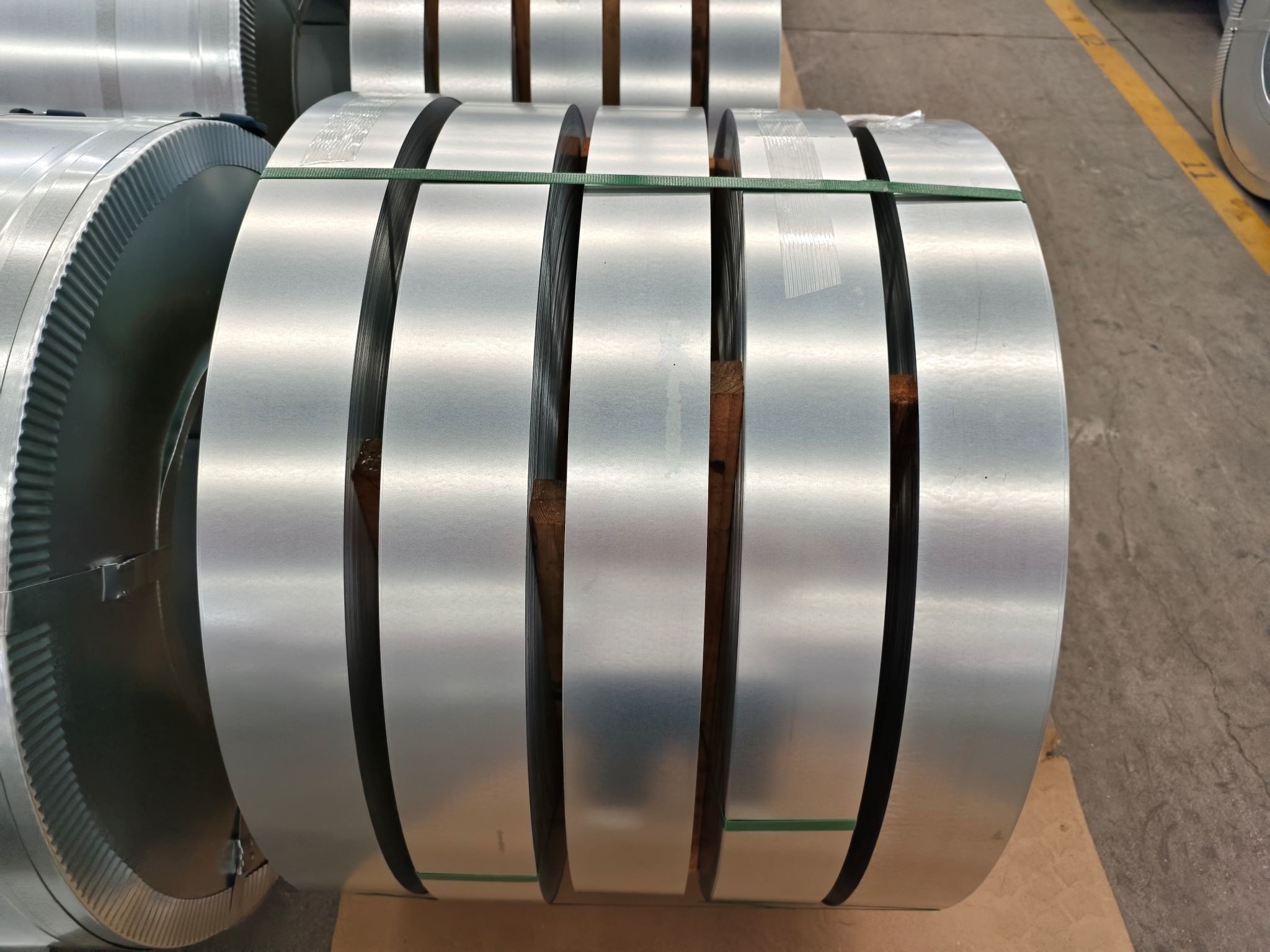

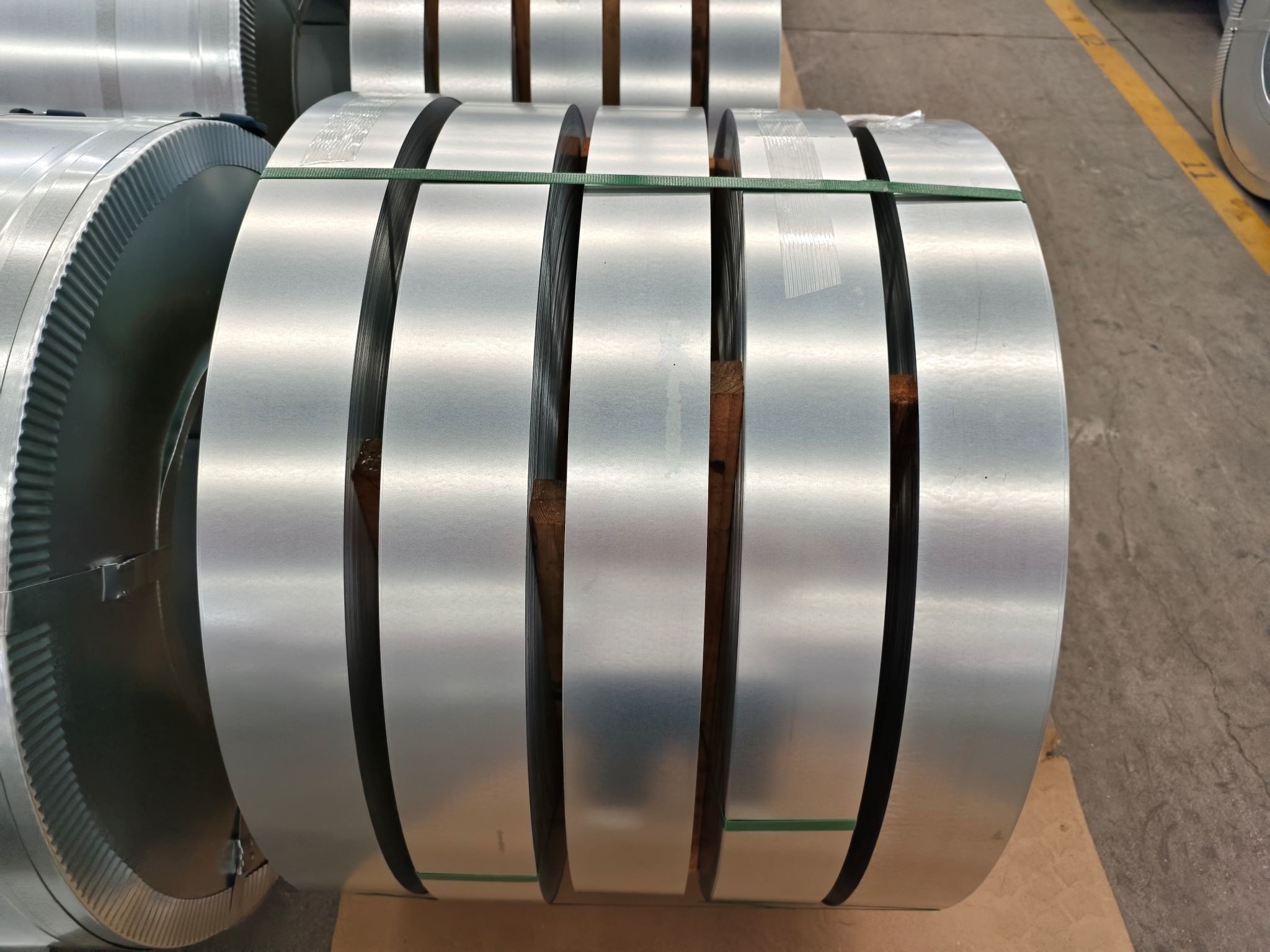

Introduction of Galvalume / Aluzinc Steel Coil and Slitted Strip

Coils

The surface of the Galvalume / Aluzinc steel sheet presents a

unique smooth, flat, and gorgeous spangle looking, with a silver

white base color. The special coating structure gives it excellent

corrosion resistance. The normal service life of Galvalume /

Aluzinc Steel Sheet and Coils can reach 25 years, and they have

good heat resistance and can be used in high-temperature

environments at 315 ℃; The adhesion between the coating and the

paint film is good, and it has good processing performance, which

can be used for stamping, shearing, welding, etc; The surface

conductivity is very good.

The coating consists of 55% aluminum, 43.5% zinc, and 1.5% silicon

in weight ratio, respectively. The production process of aluminum

zinc steel sheet is similar to that of galvanized steel plate and

aluminum plated plate, and it is a continuous melting coating

process. 55% aluminum zinc alloy coated aluminum zinc steel plate

has superior corrosion resistance compared to galvanized steel

plate of the same thickness when exposed to the same environment on

both sides. 55% aluminum zinc alloy coated aluminum zinc steel (

55% Alu-zinc Steel) plate not only has good corrosion resistance,

but also color coated products have excellent adhesion and

flexibility.

Why 55% Aluzinc Steel is Commonly Used for Light Steel Building

Frames

55% Aluzinc steel (also known as Galvalume steel) is a type of steel that has been coated with an alloy of 55% aluminum, 43.4% zinc, and 1.6% silicon. This combination provides a highly durable and

corrosion-resistant material, making it ideal for a variety of

applications, especially in light steel building frames.

Here are several reasons why 55% Aluzinc steel is favored in light steel construction, especially in regions like

Australia:

1. Superior Corrosion Resistance

Enhanced Durability: The 55% Aluzinc coating offers significantly better corrosion

resistance compared to traditional galvanized steel (which typically has a zinc coating). The aluminum content in the

alloy helps to form a protective oxide layer that resists rust and

extends the lifespan of steel products, even in harsh environments.

Longer Service Life: Aluzinc steel is up to 3 times more corrosion-resistant than galvanized steel, making it an ideal choice for construction

materials that are exposed to the elements, such as roofing,

cladding, and framing.

2. High Temperature Resistance

Thermal Stability: 55% Aluzinc steel has a high melting point (about 660°C), which makes it suitable for applications in

environments that experience high temperatures. This feature is

especially beneficial for the Australian market, which has a mix of

tropical and arid climates with high summer temperatures.

3. Excellent Heat Reflectivity

Energy Efficiency: The aluminum-zinc coating has superior reflectivity, often twice the reflectivity of galvanized steel. This makes it ideal for use in regions with

intense sunlight, like Australia, where reducing heat absorption in buildings can help improve energy efficiency by lowering cooling costs.

4. Lightweight and Strong

Structural Strength: Despite its lightweight nature, 55% Aluzinc steel provides high strength and can withstand significant mechanical stress. This is crucial

in light steel frame constructions, where strength-to-weight ratio is essential for load-bearing

capacity while maintaining ease of handling and transportation.

5. Aesthetic Appeal

Modern Look: 55% Aluzinc steel has a smooth, glossy finish that enhances the aesthetic appeal of buildings. It is often used in architectural designs for both

residential and commercial buildings, offering a clean, modern

look.

6. Resistance to Harsh Weather Conditions

Weatherproof: The Australian climate is characterized by extreme weather

conditions, including intense heat, storms, and humidity. 55% Aluzinc steel provides resilience against UV radiation, saltwater corrosion (especially near coastal areas), and the severe weather that can affect steel structures.

Index | Regular spangle / Minimum Spangle Galvalume/ 55% Aluzinc Steel Coil/Sheets |

Thickness | 0.13-2.0mm |

Width | 600~1500mm |

Zinc Coating | AZ30~AZ200 g/㎡ |

Surface Treatment | AFP (anti-finger print) Passivated / Chromated 6+,3+, Free; Oiled; Skin-passed |

Steel Grade | DX51D/52D/53D/ S250GD/280GD/350GD/550GD ASTM A792M, CS-B, SS255-SS550 JIS G3302-SGCC, SGCH (Full hard-G550) |

Coil I.D. | 508 / 610 mm |

Coil weight | 2 ~ 20 tons |

Packaging | Standard export packing ( Eye to Side) Vertical Packing ( Eye to Sky) with wooden pallet Horizontal Packing ( Eye to Side) with wooden pallet |

MOQ. | 16 tons |

Loading port | Tianjin / Qingdao / Rizhao port |

Environment | Zinc Weight/ G/sqm |

indoor environment | AZ70 or AZ100 |

Suburban environment | AZ150 or AZ100 + painting |

Urban or industrial areas | AZ150+ pre painted paint coating |

Coastal Areas | AZ180+ thick paint coating |