1.1/1.1 T2 ETP Tin Coated Used For Miscellaneous cans tea caddy

1. Introduction

• What is tinplate?

• Tinned steel sheet referred to as tinplate, commonly known as

tinplate, is a product made of tinning on a thin mild steel plate.

The tin plate produced by the hot dip process is called the hot dip

tin plate, and the tin plate produced by the electroplating process

is called the electroplated tin plate.

• Because about 98~99.8% of the weight of the tin plate is steel,

it is a coated steel variety that belongs to metallurgical

products.

Material Grades and Variants

The base steel of tinplate can vary based on its strength and

thickness, but the tin coating also comes in different weights and

compositions. These variations allow for different types of

tinplate products based on the needs of the application.

1. Tin-Free Steel (TFS) / Electrolytic Chromium Coated Steel

(ECCS):

- Instead of tin, this variant is coated with a thin layer of

chromium and chromium oxide. TFS provides similar corrosion

protection but at a lower cost. It is more commonly used in

non-food packaging applications like paint cans or aerosol

containers.

2. Single Reduced vs. Double Reduced Tinplate:

- Single Reduced Tinplate (SR): This type is cold-rolled once and

is generally used for applications requiring more ductility, such

as beverage cans or aerosol containers.

- Double Reduced Tinplate (DR): This type is cold-rolled twice,

resulting in greater strength and a thinner profile, often used for

lightweight food cans or lids.

2. Application Records:

1. Three-piece pop-top can for food and beverage:

- Market Status: This segment of the tinplate market is

well-established (mature ETP market).

- Representative Clients: Includes prominent brands such as

Wanglaoji, Redbull, and Robust.

2. Food can:

- Market Potential: Identified as one of the most promising

segments for tinplate (ETP market).

- Usage: Tinplate is extensively used for packaging various canned

foods, exemplified by brands like Huangguan, Meilin, and Gulong.

3. Screw cap and crown-shaped cap:

- Market Segmentation: ETP is specifically tailored for different

types of beer packaging.

- Dominance: It serves as a primary supplier for crown-shaped caps.

4. Spray can:

- Market Development: This segment within the tinplate market is

still evolving and offers significant growth potential.

- Usage: Tinplate is employed in the packaging of spray cans, with

room for further expansion.

5. High-grade chemical can:

- Market Focus: Chemical-grade tinplate is dedicated to packaging

high-quality paint materials.

- Application: It ensures the safe and efficient containment of

chemicals used in paints.

6. Drawn can and DRD can:

- Emerging Market: A rapidly growing segment within the tinplate

industry.

- Application: Primarily used for gift cans and other decorative

purposes, indicating its rising popularity and application

diversity.

3. Mechanical Properties of DR Tin Mill Products

GB/T2520, JIS G3303 | EN10202 | TARGET VALUE | TOLERANCE RANGE | YIELD STREGNTH/MPA | TENSILE STRENGTH/MPA |

T-1 | TS230 | 49 | 49±3 | 230±50 | 325±50 |

T-2 | TS245 | 53 | 53±3 | 245±50 | 340±50 |

T-2.5 | TS260 | 55 | 55±3 | 260±50 | 360±50 |

T-3 | TS275 | 57 | 57±3 | 275±50 | 375±50 |

T-3.5 |

| 59 | 59±3 | 290±50 | 390±50 |

T-4 | TH415 | 61 | 61±3 | 415±50 | 435±50 |

T-5 | TH435 | 65 | 65±3 | 435±50 | 460±50 |

DR-7M | TH520 | 71 | 71±3 | 520±50 | 540±50 |

DR-8 | TS550/TH550 | 73 | 73±3 | 550±50 | 570±50 |

DR-8M | TH580 | 73 | 73±3 | 580±50 | 590±50 |

DR-9 | TH620 | 76 | 76±3 | 620±50 | 625±50 |

DR-9M |

| 77 | 77±3 | 660±50 |

|

DR-10 |

| 80 | 80±3 | 690±50 |

|

The hardness is the average value of 2 samples, allowing 1 of them

to exceed the specified allowable range by 1 unit. |

a The yield strength is a reference value determined as required. b Yield strength is the average value of the two samples. The

sample is P5 in GB/T 228, and the direction of the sample is

transverse. c Due to the thickness thinning effect, the elongation is too low

and the yield strength cannot be measured. In this case, the yield

strength is replaced by the tensile strength. d For the tensile test, the width of the parallel part of the

sample is (12.5±1) mm, and the standard distance L0=50mm. Before

the test. The sample should be artificially aged for 20min at 200℃. |

Thickness | Tolerance |

Negative Tolerance | Tolerance | Positive tolerance |

0.18~0.55 SR | +1%~—3% | +2%~—2% | +0%~+3% |

0.15~0.34 DR | +1%~—3% | +2%~—2% | +0%~+3% |

Remarks | The internal control is set at-0.002mm of the thickness of the

contract order. The measurement value of the midpoint in the width

direction of the strip shall prevail. | The internal control sets the thickness of the contract order

thickness. The measurement value of the midpoint in the width

direction of the strip shall prevail. | The internal control is to set the thickness of the contract order

at +0.003mm, and the measured value at the midpoint of the strip

width direction shall prevail. |

1. The thickness of S1, S2, S3 surface and M surface shall be

measured by the flat thickness meter. (The matt surface will be

higher than the actual measurement due to surface roughness.) |

4. Formability

Deep drawing

Some types of tinplate display excellent deep-drawing property

because of a high Lankford coefficient (or coefficient of

anisotropy) associated with low in-plane anisotropy, which ensures

near-identical performance irrespective of the orientation of the

deformation in relation to the rolling direction.

Bending, rolling

Thanks to its high level of ductility (for steel with low

mechanical properties) and near-isotropic properties, tinplate can

withstand severe bending or rolling.

Expansion, embossing, beading

Tinplate is well suited to mechanical, pneumatic or hydraulic

expansion. Its expansion capacity by pneumatic or hydraulic means

can be up to 30%.

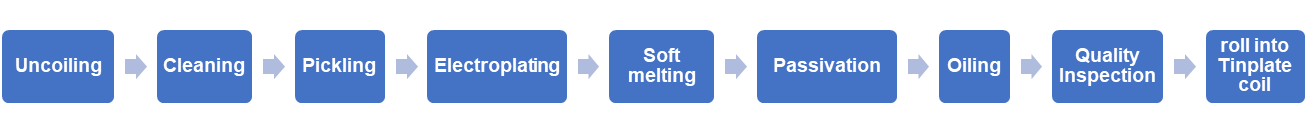

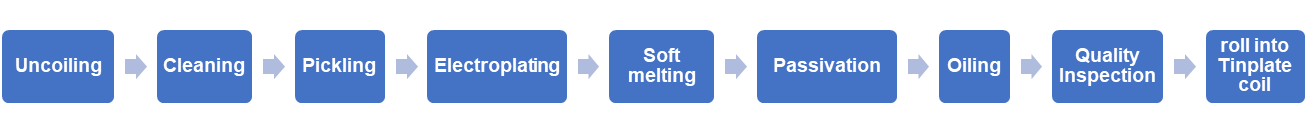

5. EQUIPMENT & PRODUCTION LINES

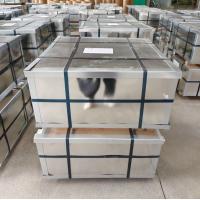

7. TINPLATE COILS & APPLICATIONS

8. APPLICATIONS

9. Packing and Marking