Tin Coated Steel Sheet ETP Packaging Materials Food Can Beverage

Can

1. Introduction

Tin mill products include electrolytic tinplate, and electrolytic

chromium coated steel (also referred to as tin free steel or TFS),

and Black Plate. Tinplate is a thin steel sheet coated by tin,

while TFS is an electrolytic chrome plated steel consisting of a

thin layer of chromium and a layer of chromium oxide deposited on

the steel base. The coating gives both of them a beautiful,

metallic luster as well as excellent properties in corrosion

resistance and paintability.

Modern industrial tinplate is usually a cold-rolled, low carbon

sheet coated with commercial pure tin on both sides, which combines

the strength and formability of steel with the corrosion

resistance, weldability and appearance of tin. Tinplate is widely

used in the food industry and a variety of containers, stamped

products, packaging materials for non-food industry, such as food

cans, spray cans, bottle caps, gas containing beverage cans,

packaging materials and non-packaging materials (home appliances,

toys, stationery, engineering).

We are the professional manufacturer in China with advanced

technical equipments, first class inspection devices and

substantial experience in production. It possesses integrated

process lines including smelting, hot rolling, cold rolling and

coating. The product catalogue covers ETP and TFS with an annual

output over 1 million tons. Our tin mill products are widely sold

and used throughout the world in application of packaging of food,

beverage and industrial goods and enjoy high reputation in the

international market.

2. Features of ETP Products

By selecting a proper coating weight, appropriate corrosion

resistance is obtained against container contents.

Printing is beautifully finished using various lacquers and inks.

TIN PLATE is widely used for making various types of cans by

soldering or welding.

By selecting a proper temper grade, appropriate formability is

obtained for various applications as well as the required strength

after forming.

Electrolytic ETP is characterized by its beautiful metallic luster.

Products with various kinds of surface roughness are produced by

selecting the surface finish of the substrate steel sheet.

3. Mechanical Properties of DR Tin Mill Products

Nominal Coating Weight g/m | Standard (g/m2 ) |

| Average / side | Single point | Target Value |

| Minimum | Minimum |

| 1.1 | 0.9 | 0.8 | 1.0 |

| 1.4 | 1.12 | 1.08 | 1.3 |

| 2.0 | 1.6 | 1.56 | 1.9 |

| 2.2 | 1.8 | 1.76 | 2.1 |

| 2.4 | 1.92 | 1.88 | 2.3 |

| 2.5 | 2.0 | 1.98 | 2.4 |

| 2.8 | 2.45 | 2.2 | 2.6 |

| 3.0 | 2.61 | 2.5 | 2.8 |

| 4.0 | 3.48 | 3.2 | 3.8 |

| 5.0 | 4.35 | 4.2 | 4.8 |

| 5.6 | 5.05 | 4.8 | 5.4 |

| 8.4 | 7.55 | 7.55 | 8.4 |

| 11.2 | 10.1 | 10.1 | 11.2 |

GB/T2520, JIS G3303 | EN10202 | TARGET VALUE | TOLERANCE RANGE | YIELD STREGNTH/MPA | TENSILE STRENGTH/MPA |

T-1 | TS230 | 49 | 49±3 | 230±50 | 325±50 |

T-2 | TS245 | 53 | 53±3 | 245±50 | 340±50 |

T-2.5 | TS260 | 55 | 55±3 | 260±50 | 360±50 |

T-3 | TS275 | 57 | 57±3 | 275±50 | 375±50 |

T-3.5 |

| 59 | 59±3 | 290±50 | 390±50 |

T-4 | TH415 | 61 | 61±3 | 415±50 | 435±50 |

T-5 | TH435 | 65 | 65±3 | 435±50 | 460±50 |

DR-7M | TH520 | 71 | 71±3 | 520±50 | 540±50 |

DR-8 | TS550/TH550 | 73 | 73±3 | 550±50 | 570±50 |

DR-8M | TH580 | 73 | 73±3 | 580±50 | 590±50 |

DR-9 | TH620 | 76 | 76±3 | 620±50 | 625±50 |

DR-9M |

| 77 | 77±3 | 660±50 |

|

DR-10 |

| 80 | 80±3 | 690±50 |

|

The hardness is the average value of 2 samples, allowing 1 of them

to exceed the specified allowable range by 1 unit. |

a The yield strength is a reference value determined as required. b Yield strength is the average value of the two samples. The

sample is P5 in GB/T 228, and the direction of the sample is

transverse. c Due to the thickness thinning effect, the elongation is too low

and the yield strength cannot be measured. In this case, the yield

strength is replaced by the tensile strength. d For the tensile test, the width of the parallel part of the

sample is (12.5±1) mm, and the standard distance L0=50mm. Before

the test. The sample should be artificially aged for 20min at 200℃. |

Thickness | Tolerance |

Negative Tolerance | Tolerance | Positive tolerance |

0.18~0.55 SR | +1%~—3% | +2%~—2% | +0%~+3% |

0.15~0.34 DR | +1%~—3% | +2%~—2% | +0%~+3% |

Remarks | The internal control is set at-0.002mm of the thickness of the

contract order. The measurement value of the midpoint in the width

direction of the strip shall prevail. | The internal control sets the thickness of the contract order

thickness. The measurement value of the midpoint in the width

direction of the strip shall prevail. | The internal control is to set the thickness of the contract order

at +0.003mm, and the measured value at the midpoint of the strip

width direction shall prevail. |

1. The thickness of S1, S2, S3 surface and M surface shall be

measured by the flat thickness meter. (The matt surface will be

higher than the actual measurement due to surface roughness.) |

Available Width | Width Tolerance |

General order (normal production requirements) | High-precision ordering |

750~1050mm | +0~+3( aim +0~+1.5) | +0~+2 (aim +0~+1.0) |

4. Product Standard

ETP orders are placed with Baosteel in accordance with Q/BQB

450-2009 standard which uses in a non-equivalent to JIS G

3303:2008, DIN EN 10202:2001, EN 10203 standards.

TFS orders are placed with Baosteel in accordance with Q/BQB

455-2009 standard which uses in a non-equivalent to JIS G

3315:2008, DIN EN 10202:2001, EN 10203 standards.

5. Usage Precautions for ETP

- As ETP is covered by soft metallic tin coatings, due precautions

should be taken not to cause scratches by rough handling or

vibration during transportation.

- Paintability, printability, solderability, and mechanical

properties of ETP tend to 收deteriorate as time elapses after

production. Use as soon as possible after delivery.

- Although ETP has excellent corrosion resistance, it tends to rust

in a humid atmosphere. Use as soon as possible after unpacking.

- Tin is dissolved by a strongly alkaline solution. When using ETP

for making cans for alkaline contents, paint the internal surface.

- As contents that contain sulfur cause blackening of the ETP

surface, paint the internal surface.

6. EQUIPMENT & PRODUCTION LINES

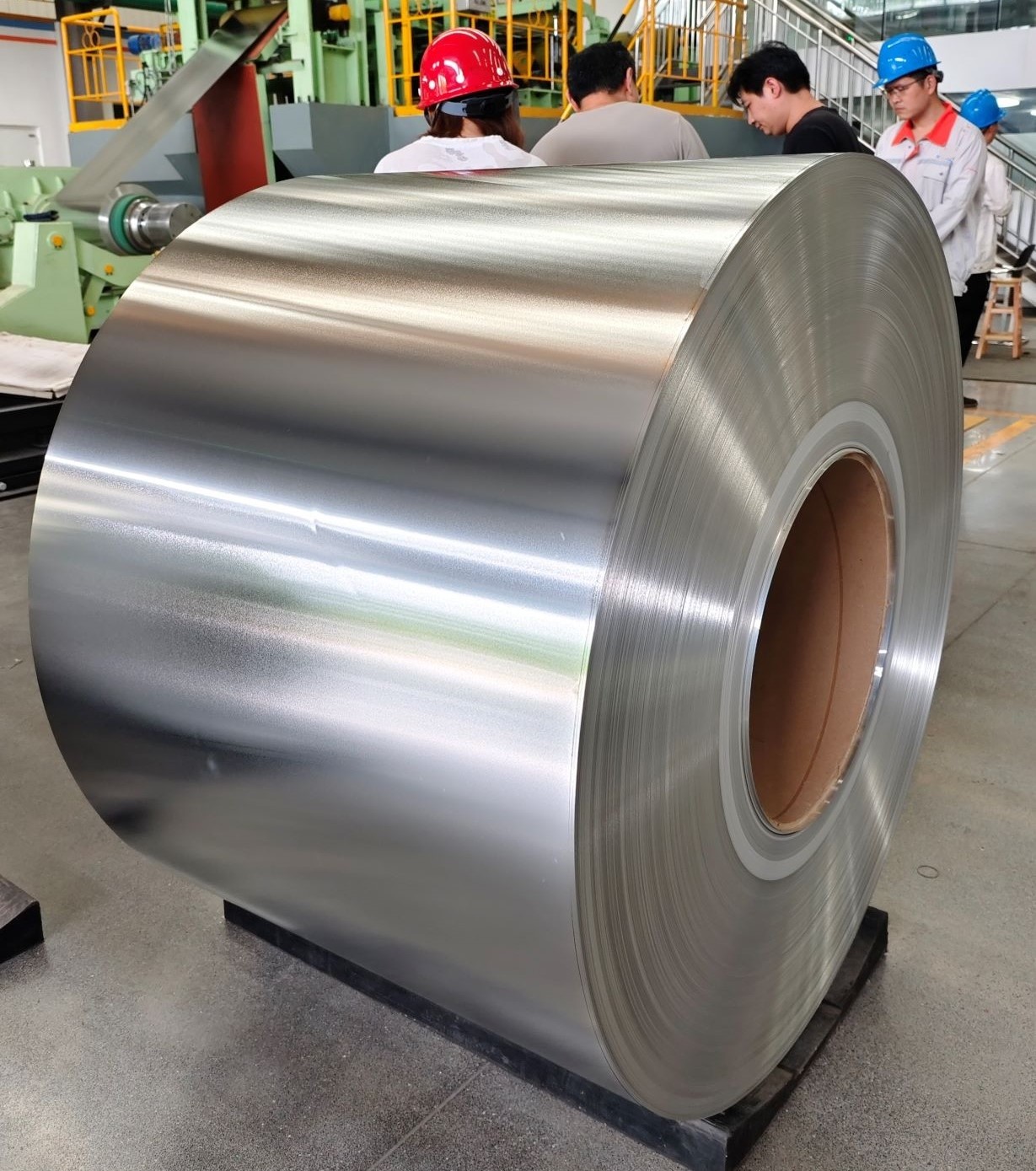

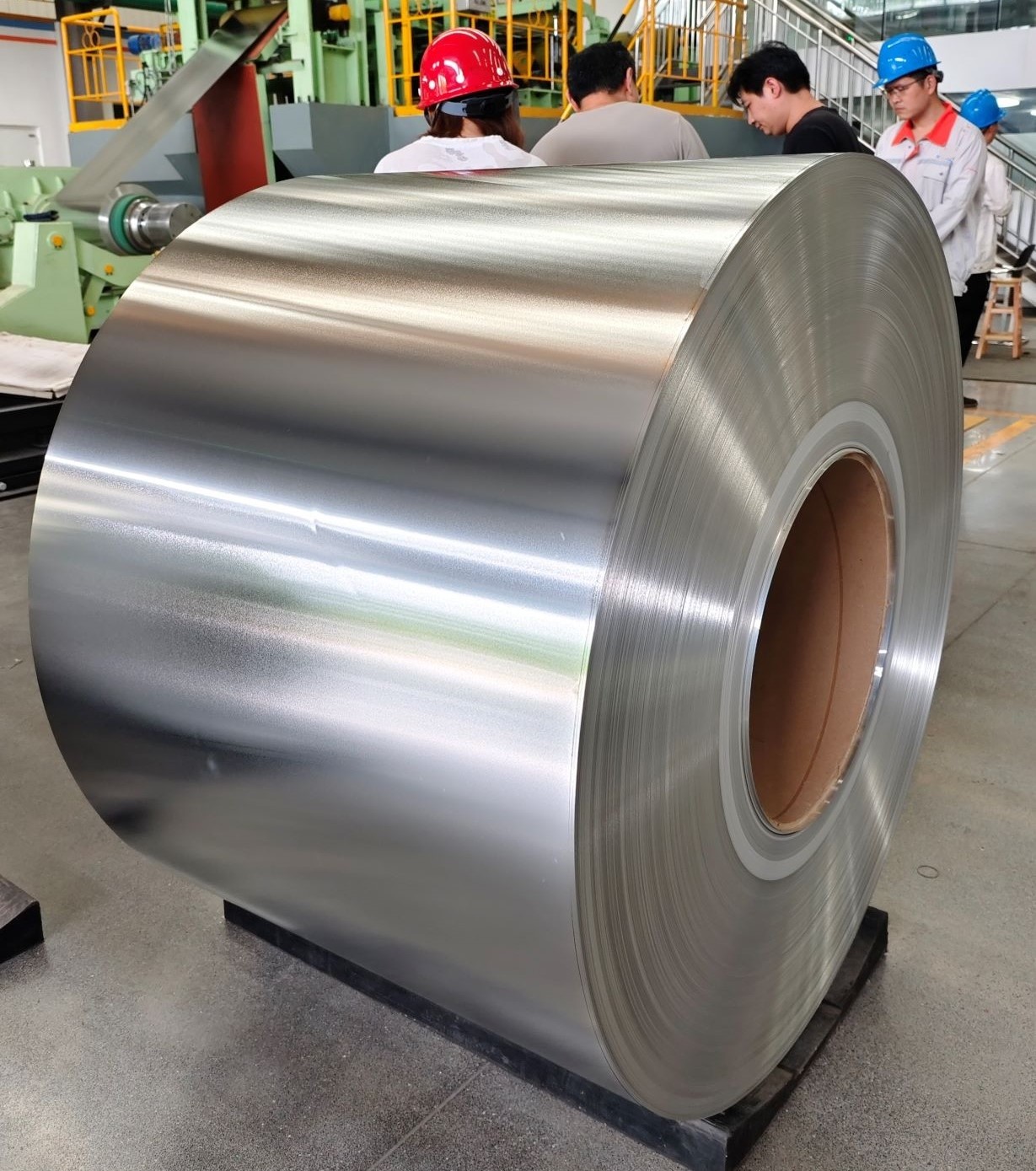

7. TINPLATE COILS

8. APPLICATIONS

Consumer Packaging and Industrial Packaging

TINPALTE

ETP is primarily used for packaging foodstuffs and beverages, but

it is also used in containers

for oils, grease, paints, polishes, chemicals and many other

products. Aerosol containers and

caps and closures are also made from ETP.

TFS

TFS are most frequently used for can tops, screw and lug caps, snap

and press-on closures and shallow-drawn food cans.

in Electronics

– Electrodes, Cable tape, Magnetic screen covers, etc.

in Engineering

– Automotive oil filters, Automotive air filters, Gaskets, etc.

in Construction

– Gas meter internal components, Heat exchangers, etc.

9. Packing and Marking

Offers coils and sheets, coil packed in a vertical form or a

horizontal.

A label that indicates the manufacturing history is affixed to the

outside of the packaging. In addition, a service card is contained

inside.

With regard to types of packing and markings, please consult us.