Polar White Beckers Metal Roof PPGL AZ150 0.80*1225

Chromadek IBR Matt Textured Steel Sheet Z275 PPGI

Product Category

Color coated sheet coil starts with a substrate, which can be hot

rolled, galvanized, aluminum-zinc plated, cold rolled, tinned,

stainless steel, or other materials. After surface pretreatment

(degreasing and chemical treatment), one or more layers of liquid

paint are applied using a roller coating method. The sheet is then

baked and cooled to produce coated steel, which is made into color

coated coils. These coils are primarily used in building roofs,

walls, steel structure plants, and home appliances, as well as in

purification and clean plants. Common specifications range from 0.2

to 1.0 mm in thickness, with common domestic widths of 1000 and

1200 mm, and main export widths of 940, 1200, 1219, and 1250 mm.

- Classified according to the use of substrates. Usually used for

organic coated steel plate substrate: cold rolled sheet, hot

galvanized sheet, electric galvanized sheet, alloying plate,

galvanized aluminium plate, galvanized zinc alloy plate, tin plate,

chrome plate, aluminium plate and so on.

- Classified according to the processing technology. According to the

different coating methods, there are roller coating method,

spraying method, powder method, compound film method, printing

method and other organic coating of steel. According to the

different coating times, there is a coating and baking, two coating

and baking, three coating and baking, four coating and four baking

and other different processes coating made of organic coated steel.

According to embossing or printing processing points, can be

subdivided into wood grain plate, marble grain, skin grain, cement

mortar grain coating steel plate.

- According to the type of coating classification. Usually classified

according to the paint used to make organic coating, PVC coated

steel, polycool coated steel, acrylic coated steel, fluorocarbon

coated steel, silicone polycool coated steel and so on.

- Classified by coating performance. According to the organic coating

performance characteristics, there are high weathering coating

plate, high temperature coating plate, self-extinguishing coating

plate, sterilisation coating plate, non-stick snow coating plate,

fingerprint-resistant coating plate, and self-lubricating coating

plate.

- According to the special coating and use classification. Such as

epoxy zinc-rich coatings, cold rolled steel as the substrate of the

organic coating of steel, there are surface flocking steel, as well

as some special machine-coated laminates, such as post wood film

board, sandwich panels, shock boards, etc..

Coating Structures:

Coating structures refer to the specific application methods and

baking processes used to apply protective coatings to surfaces,

enhancing their durability and performance. Here are the detailed

descriptions of common coating structures:

- 2/1 Coating Structure:

- Description: The upper surface is coated twice, while the lower surface

receives one coating layer. The coated surfaces undergo two rounds

of baking.

- Characteristics: Offers moderate corrosion resistance and scratch resistance. Known

for its strong adhesion properties.

- Applications: Primarily used in sandwich panel construction where adhesion is

critical for bonding layers.

- 2/1M Coating Structure:

- Description: Both the upper and lower surfaces are coated twice, followed by a

single round of baking.

- Characteristics: Provides good corrosion resistance, scratch resistance, and

molding properties. Ensures strong adhesion to substrates.

- Applications: Suitable for single-layer compression molding panels and versatile

enough for use in pressboards and sandwich panels.

- 2/2 Coating Structure:

- Description: Both the top and bottom surfaces receive two coats of paint, each

followed by two rounds of baking.

- Characteristics: Offers high corrosion resistance, scratch resistance, and

excellent processability due to the dual-layer coating.

- Applications: Predominantly used in single-layer pressboards where robust

protection and superior adhesion are required.

Detailed Parameters:

| Coating performance |

| CATEGORY | T Bending | Impacting | Salt spray test(hours) | MEK | Hardness | Gloss 60° | Color Tolerance ΔE |

| PE | ≤3T | ≥9 | ≥500 | ≥100 | ≥F | 10-85 | ≤0.8 |

| SMP | ≤3T | ≥9 | ≥500 | ≥100 | ≥F | 10-85 | ≤0.8 |

| HDP | ≤2T | ≥9 | ≥1000 | ≥100 | ≥HB | 10-85 | ≤0.8 |

| PVDF | ≤2T | ≥9 | ≥1000 | ≥100 | ≥HB | 10-85 | ≤0.8 |

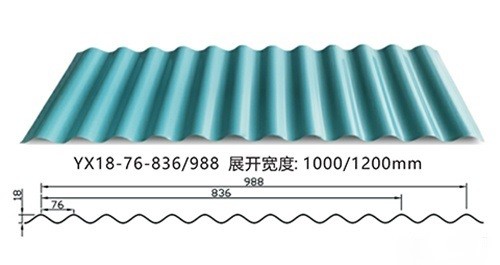

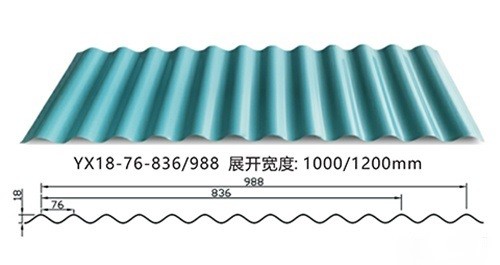

Corrugated Sheet Types

Paint Suppliers & Partners:

We only choose the top-level paint suppliers for our pre-painted

steel coils and sheets,

AkzoNobel, Sherwin-Williams Valspar, Beckers, PPG Industries,

Nippon, KCC are our solid paint suppliers.

Their best paint materials decide our steel coils quality.

Package & Delivery Shipment :

Delivery time: 30 days deliver to loading port

Shipment Methods: Container, Breakbulk, Railway, Trucks

Projects: