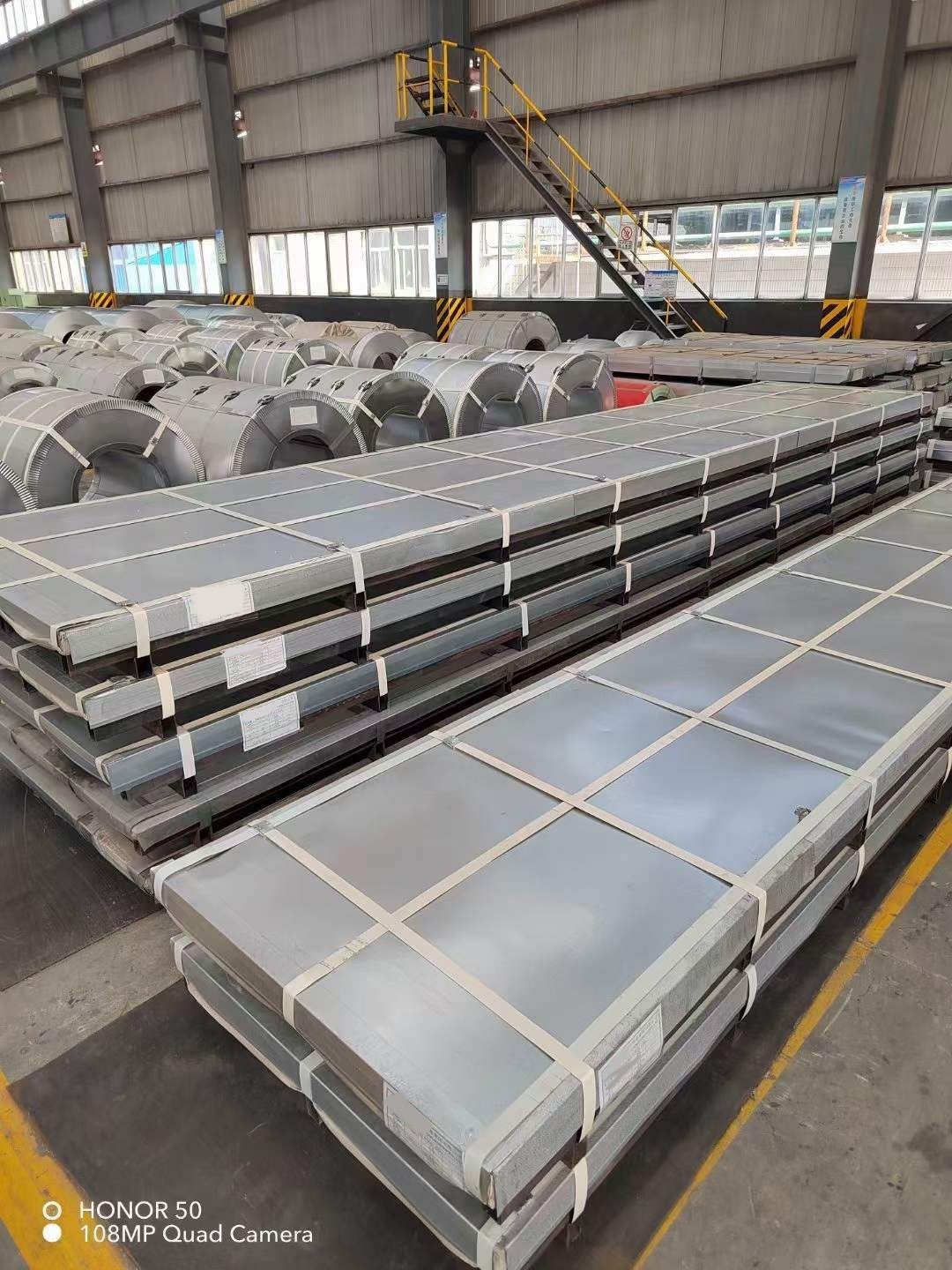

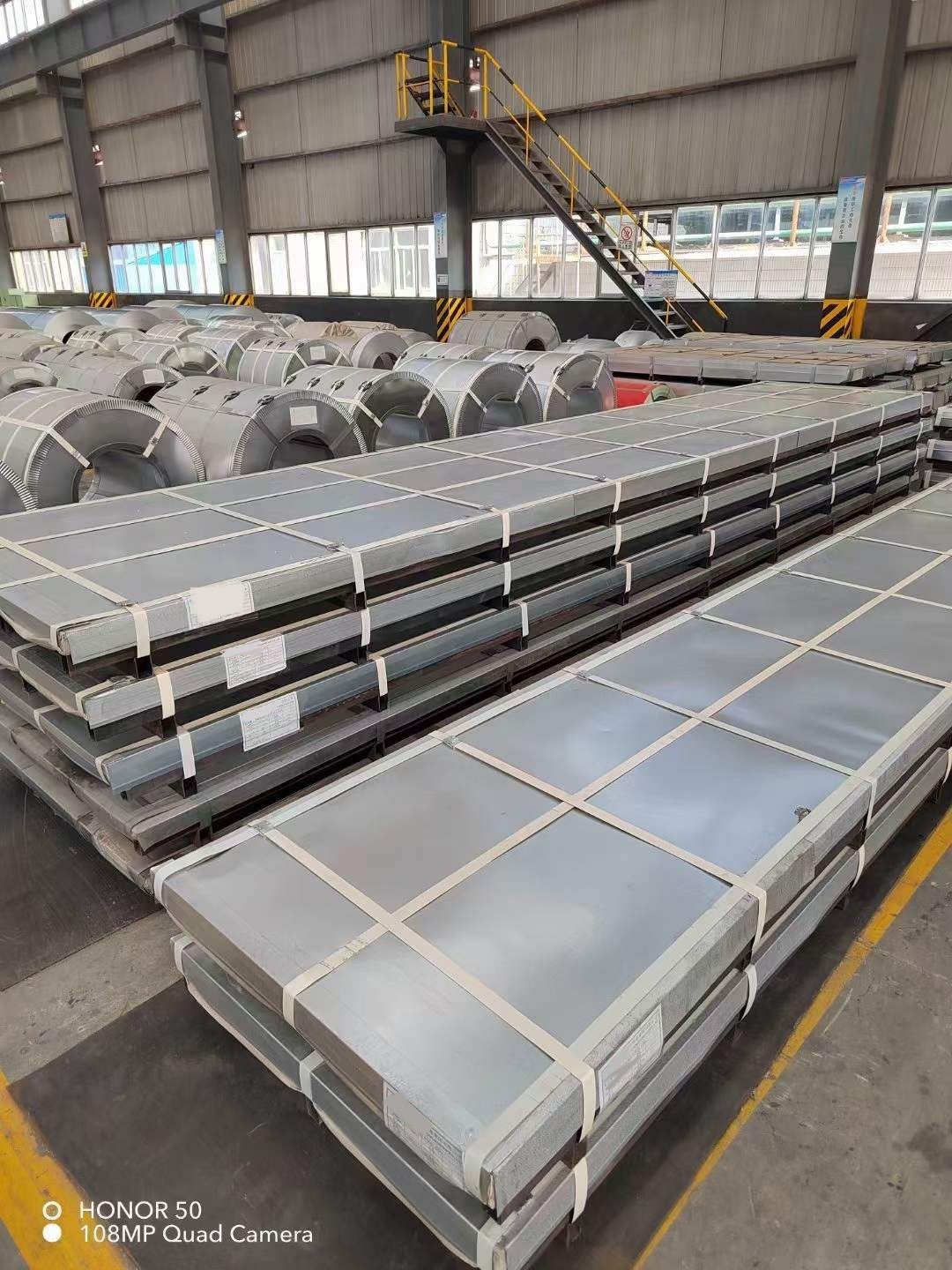

Description

Galvanized shingles are steel sheets with a zinc coating on the

surface.

Galvanized roof tiles are steel sheets coated with a layer of zinc.

Galvanizing is an economical and effective method of corrosion

protection, and approximately half of the world's zinc production

is used for this process.

Galvanized roof tiles are manufactured by coating the surface of a

steel sheet with a metallic zinc layer, which prevents surface

corrosion and prolongs its service life; this zinc-coated steel

sheet is called galvanized steel sheet.

Product advantages

Galvanized shingles are widely used in various environments and

have a long service life of corrosion protection, which depends on

the environment.

Low processing costs, galvanized shingles have lower corrosion

costs than other coatings.

Durability, in suburban environments, standard galvanized

anti-corrosion coatings remain intact for more than 50 years

without repair. In urban and marine areas, standard galvanized

anti-corrosion coatings last up to 20 years without repair.

Reliability. The durability of the coating is relatively reliable

because the galvanized coating is metallurgically bonded to the

steel and becomes part of the hard surface.

The coating is tough and the galvanized layer forms a special

metallurgical structure that can withstand mechanical damage during

transportation and use.

Integrity protection

all parts of the plated component are galvanized, even in

depressions, sharp corners and hidden areas.

Saving time and effort. Galvanizing is faster than other painting

methods and avoids the time needed for on-site painting after

installation.

Usesages

Galvanized tiles are mainly used in the construction, light

industrial, automotive, agricultural, fishing and commercial

sectors. The construction industry is mainly used in the

manufacture of corrosion-resistant panels for industrial and civil

engineering roofs, roof gratings, etc.; light industry for the

housings of their manufacturing equipment, particular chimneys,

kitchen utensils, etc. The automotive industry mainly for the

manufacture of corrosion-resistant parts for vehicles; the

agricultural, livestock and fishing industries mainly for the

storage and transportation of grain, meat and seafood products,

frozen processing equipment, etc.; the commercial sector is mainly

used for the manufacture of galvanized products, frozen products,

etc.; the commercial sector is mainly used for the storage of

materials, packaging equipment, etc.

| Standard | JIS / EN / ASTM Standard |

| Grades | SGCC/SGCD/SGCE,SGHC,SGC280GD/SGC340/SGC400/SGC440/SGC490/SGC570 |

| S220GD/S250GD/S280GD/S320GD/S350GD/S550GD |

| SS230/SS250/SS275/SS340/SS380/SS410/SS480/SS550 |

| A653 CS-A/ CS-B, ASTM A653Gr.33/Gr.37/Gr.40/Gr.50/Gr.80, |

| DX51D/DX52D/DX53D/DX54D/DX56D etc. |

| H220PD/H300PD/H180YD/H200YD/H260YD |

| H180BD/H220BD/H260BD/H300BD |

| H260LAD/H340LAD/H420LAD |

| DP590/DP780 |

| Coating | Z60-Z450 or G40/G60/G90/G120/G150 |

| Spangle | Regular spangle / Minimized spangle / Zero spangle |

| Sizes | Thickness:0.12mm-4.5mm Width: 900mm-1500mm |

Product Description:

Steel Material Dx51d, Dx52D, Dx53D Zinc Coated Corrugated

Galvanized Steel Roofing Sheet

GI Roofing Steel Sheet common size as follows

1) 762mm to 665mm(after corrugated)and 9 waves

2) 914mm to 750mm(after corrugated)and 11 waves

3) 1000mm to 890 or 900mm(after corrugated)and 12 or 14 waves

| Thick | 0.13-1.0/BWG/AWG |

| Width before corrugated | 762-1200 mm |

| Width after corrugated | 600-1000mm |

| Zinc Coating | 30-275G/M2 |

| Weight | 2-4 Tons |

| Standard | ASTM-A653; JIS G3302; EN10147;etc |

| Payment Terms | T/T, LC, Paypal, O/A, DP |

| Regular Order | 25 tons or one container, for less quantity, to contact with us for

details |

| Hardness | Soft hard(HRB60),medium hard(HRB60-85),full hard(HRB85-95) |

| Surface Structure | Regular spangle,Minimum spangle, Zero spangle, Big spangle |

| Surface Treatment | Chromated/Non-Chromated, Oiled/Non-oiled, Skin pass |

| Index | Regular spangle | Zero spangle |

| Galvanized Steel Coil/Sheets | Galvanized Steel Coil/Sheets |

| Thickness | 0.13-2.50mm | 0.20-2.0mm |

| Width | 600~1500mm | 600~1500mm |

| Zinc Coating | Z30~Z400 g/㎡ | Z30~Z275 g/㎡ |

| Surface Treatment | Passivated / Chromated 6+,3+, Free; | Skin passed, Chromated 6+, 3+, Free |

| Oiled | Oiled, AFP (anti-finger print) |

| Steel Grade | DX51D/52D/53D/ | DX51D/52D/53D/ |

| S250GD/280GD/350GD/550GD | S250GD/280GD/350GD/550GD |

| ASTM A653M, SS255-SS550 | ASTM A653M, SS255-SS550 |

| JIS G3302-SGCC, SGCH (Full hard-G550) | JIS G3302-SGCC, SGCH (Full hard-G550) |

| Coil I.D. | 508 / 610 mm | 508 / 610 mm |

| Coil weight | 2 ~ 20 tons | 2 ~ 20 tons |

| Packaging | Standard export packing ( Eye to Side) |

| Vertical Packing ( Eye to Sky) with wooden pallet |

| Horizontal Packing ( Eye to Side) with wooden pallet |

| MOQ. | 16 tons | 16 tons |

| Loading port | Tianjin / Qingdao / Rizhao port | |

| Usage | Purlins, light steel frame, ventilation duct, downpipe, round pipe,

square pipe, roof panel, corrugated sheets. | Coated steel coil production, household appliances ( pre-coated

metal PCM) |

| Roof panel, corrugated sheets |

| Application | Steel Grade | Standard | Function & Characteristics |

| Stamping Steel China Steel Grade | DX51D+Z, DX51D DX52D+Z, DX52D DX53D+Z, DX53D DX54D+Z, DX54D | GB/T 2518 | Including materials for general use, mechanical biting(LFQ Lock

Forming quality), deep drawing, and ultra deep drawing. The coating

and welding performance of alloying hot-dip galvanizing are

superior. |

| Structural Steel | S250GD+Z, S250GD | GB/T 2518 | Structural steel is generally used for important purposes such as

load-bearing, and is often used in steel structure projects, with

good corrosion resistance and processing performance |

| S280GD+Z, S280GD |

| S350GD+Z, S350GD |

| S450GD+Z, S450GD |

| S500GD+Z, S500GD |

| S550GD+Z, S550GD |