Shandong Decho Building Materials Technology Co., Ltd (hereafter called “DBM” ) is a professional manufacturer and exporting company of

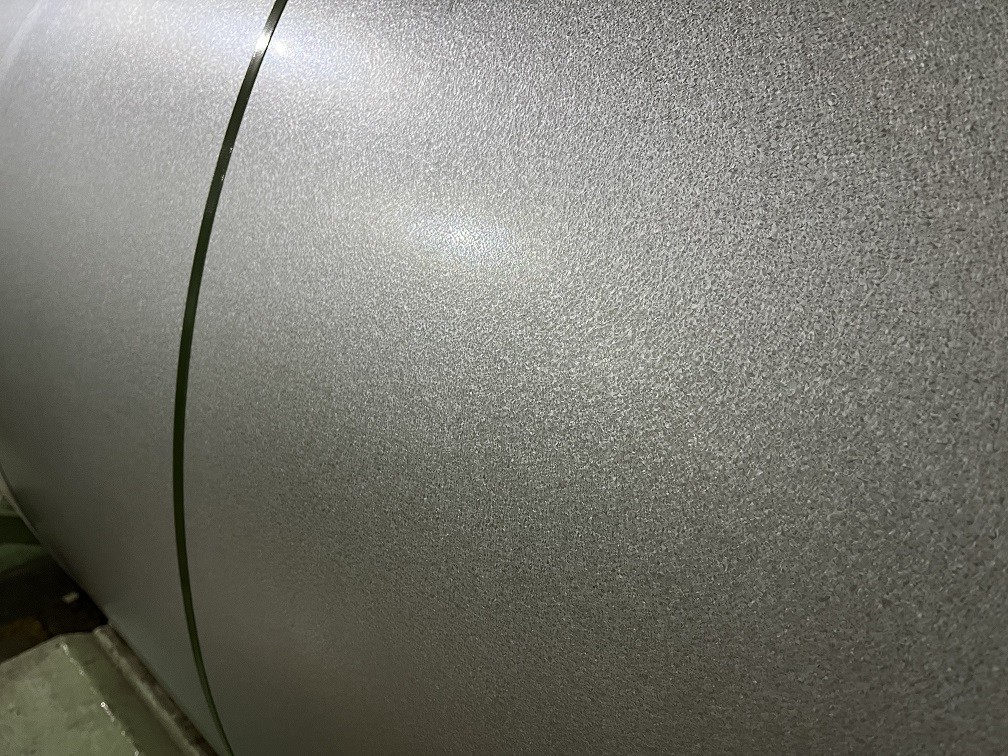

coated steel coils and sheets, with over 13 years of experience in

steel industry and 11 years of steel mill work experience, with

extensive product knowledge and experience in production process,

especially for the supply of coated steel coils with a stable and

reliable supply chain of manufacturers and logistics.

DBM is always in pursuit of and committed to providing high quality

products and services. Our company has professional quality

inspection team members, for each batch of orders can be fully

on-site testing and provide test reports, can also accept any

third-party testing company on-site testing, we can do is to ensure

that each order goods delivered to a high standard, to achieve

customer satisfaction, to achieve win-win cooperation.

DBM can meet the need to use colour steel plate as raw material for

building. Decho Building Materials colour steel plate is mainly

processed into, for example, colour steel corrugated board or

colour steel composite sandwich board after our colour steel plate

is widely used in the construction of airports, freezers, steel

plants, warehouses, and other industrial buildings and commercial

buildings, such as the roof of the colour steel tiles, colour steel

plate sandwich walls and doors.

DBM only focus on high standard coated coils with warranty service, We

are your strict gatekeeper and faithful partner in China import ,

We always been committed to becoming your long-term reliable

supplier in China.