Wall Cladding Interior Decoration Wood Grain Steel Coils

Pre-Painted Galvanised Steel Coil Z180 PE 15 Years Warranty

Product Introduction Section

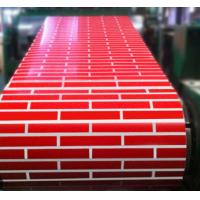

Printed color coated steel and aluminum coil

The printed color coated plate has decorative effects such as wood

grain, brick grain, camouflage, marble, etc.

The printing color coated coils usually adopts the gravure printing

process, which uses steel rollers for laser engraving of the

required patterns to transfer the ink onto the surface of the steel

plate.

- Firstly, the substrate is subjected to pre-treatment such as

degreasing, cleaning, and passivation. After the pre-treatment

process is completed, a layer of matching color primer is applied

to the surface of the steel plate. According to the application

field of the printed color coated plate, the primer can be divided

into polyester, polyurethane, and other coating types. After the

primer is dried and bakeout, printing is carried out using ink.

According to the complexity of the pattern, it can be divided into

single color printing and multi color printing. After the ink

printing is dried and baked, Re-coating the varnish, including

polyester, High durable polyester (HDP), fluorocarbon PVDF and

other paint coating types. After the primer is dried and

solidified, the entire production process of printed color coated

boards is completed through processes such as cooling, coiling, and

shearing.

- The above is a two-coating and two-baking production process, for

the higher requirements of printing colour coated panels, such as

fluorocarbon printing colour coated panels, you can use the

three-coating and three-baking process, after the roller coating of

polyurethane primer, then coated with a layer of fluorocarbon

topcoat of the matching colours, and then ink printing, and then

finally coated with a layer of fluorocarbon varnish.

Printed steel sheet can be used in household appliances, furniture,

doors and windows, signs, outdoor decoration and so on.

The substrate can be cold-rolled substrate, electro-galvanised

substrate and hot-dip galvanised substrate, aluminium-zinc plated

steel sheet, and materials with suitable mechanical properties

should be selected according to the different uses.

- Hot-dip galvanised substrates : Hot-dip galvanised substrates can be selected according to the

amount of galvanisation, zinc coating pattern and surface

finishing.

- Aluminium-zinc plated steel sheets : Since its introduction to the world market in the 1970s,

aluminium-zinc plated steel sheet has become the most popular steel

sheet for roofing and walling. The hot-dip alloy coating of

aluminium-zinc-plated steel contains 55% aluminium, 43.5% zinc and

1.5% silicon, effectively combining the strength of steel, the

corrosion resistance of aluminium and the sacrificial protection of

zinc against cut-outs and intervals. In similar environments,

galvanised steel sheet with the same coating thickness lasts about

four times longer than galvanised steel sheet. Aluminium-zinc

plated steel is a superior price/performance ratio product, costing

far less than stainless steel or aluminium, and has a pleasing

light silver-grey finish.

Second, the choice of paint base

Primer type and film thickness Primer has four types: epoxy resin,

polyester resin, acrylic resin and polyurethane resin. Generally,

the primer is selected according to the purpose of the product

base, the occasion of use, the degree of processing, as well as the

matching of the topcoat. The film thickness of primer is usually

5um.

1,Epoxy primer

Good adhesion with the substrate, water resistance, alkali

resistance, good chemical resistance, is the earliest coil with

primer, flexibility is not as good as other primers.

2,Polyester primer

Good adhesion with the substrate, excellent flexibility, more

sensitive to humid environments, less resistant to chemicals than

epoxy primer.

3,Water-soluble acrylic primer

Good adhesion with the substrate, excellent flexibility, organic

solvent content, low temperature curing, should not be stored in a

humid environment, high pretreatment requirements.

4,Polyurethane primer

With chemical resistance, friction resistance, durability, good

flexibility.

Topcoat types and film thicknesses

The most commonly used topcoats are polyester, silicone-modified

polyester, polyvinyl chloride plastisol and polyvinylidene

fluoride.

1,Polyester

Good adhesion, wide range of formability and outdoor durability,

medium chemical resistance.

2,Silicon modified polyester

Good hardness, abrasion resistance and heat resistance of the

coating film, as well as good outdoor durability and not chalking,

gloss retention and flexibility is limited, the cost of medium to

high.

3,Polyvinylidene chloride

Good formability and colour retention, excellent outdoor durability

and resistance to chalking, solvent resistance, limited colours,

expensive.

4,Polyvinyl chloride plastisol

Excellent external durability and chemical resistance, damage

resistance, beautiful, need special primer matching. Surface can

have a smooth type, for pressing or automatic shrinkage type to

form patterns. Coating thickness is generally greater than 100um,

in addition to plastic sol, in general, the primer plus topcoat

coating thickness >= 20um, the product performance can achieve

the intended purpose.

Third, the colour and gloss of the paint

Generally, the standard colour can be selected according to the

production factory, which can shorten the workload in the

pre-production stage. If you need special colours, because the

coating first in the coating factory for small samples of

configuration, and the performance of the requirements before

production, so from the order to the colour plate production time

will be longer. The surface gloss of the coating measured with a

reflection angle of 60 degrees, the larger the value, the higher

the gloss, the coatings used in the construction of medium-gloss

and matt, between 30-55. This is because the high gloss coatings

used on the building on the reflection of sunlight is strong,

harsh; if indoors, at night in the light is easy to cause visual

fatigue.

| SPECIFICATION |

THICKNESS

| STEEL : 0.20MM-1.50MM |

| ALUMINUM: 0.20-3.0MM |

| WIDTH | 600MM-1500MM |

| SHEET LENGTH | MAX 5.8METERS |

| ZINC COATING | Z40-Z275G/M2 AZ30-AZ200G/M2 |

| PAINT STRUCTURE | 2/1, 2/2, 3/2, 3/3 |

| PAINT COATING | Top side: 15μm-55μm Back side: 5μm-30μm |

| PAINT | RMP( REGULAR MODIFY POLYESTER), SMP, HDP, SUPER-SMP, SUPER-HDP,

PVDF |

| PAINT BRAND | VALSPAR(SHERWIN-WILLIAMS), AKZONOBEL, PPG, BECKERS, KCC, NIPPON,

CHINESE LOCAL BRANDS |

| PAINT SURFACE | GLOSS COLORS- RAL CODE TEXTURED /MATT/WRINKLE COLORS PRINTECH PATTERN COLORS – WOODEN PATTERN, BRICK PATTERN |

| SURFACE PROTECT | PROTECTIVE FILM ( PVC FILM ) 30/40/50/80/100UM |

STEEL GRADE | EN10346-DX51D/DX52D/DX53D, S250GD/280GD/350GD/550GD, ASTM A653M, CS-B, SS255-SS550 AS1397 G250/G300/G350/G550 JIS G3302-SGCC, SGCH (FULL HARD-G550) |

COIL ID. | 508MM 610MM |

| COIL WEIGHT | 2TONS-10TONS |

| PACKAGING | STANDARD EXPORTING PACKAGE (EYE TO SIDE) NO PALLET VERTICAL PACKAGE ( EYE TO SKY ) WITH WOODEN PALLET HORIZONTAL PACKAGE ( EYE TO SIDE) WITH WOODEN PALLET |

| MILL ORIGIN | GUANZHOU, ZHONGGUAN, HONGJI |

| MOQ. | 25 TONS/COLOR/SIZE |

| LODING PORT | QINGDAO PORT, TIANJIN PORT |

AVAILABLE WOOD GRAIN PATTERNS

( CUSTOMIZED ACCORDING TO CUSTOMER REQUIREMENT )